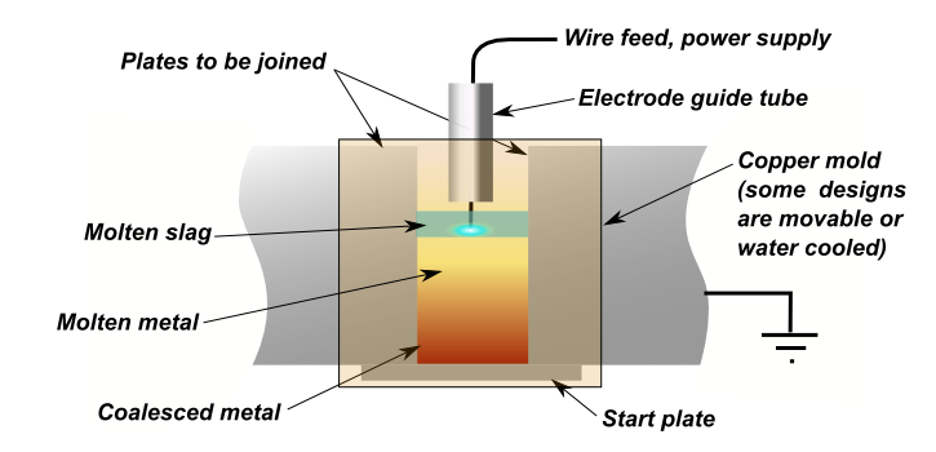

In the late 1930’s, electro-slag welding (ESW) process was first created in the United States then patented by Robert Hopkins in 1940. The E.O. Paton Institute in the Ukraine developed ESW further with other metals and materials. ESW is a process that produces coalescence of metals with molten slag that melts the filler metal and the surface of the workpieces. Slag is formed when iron or iron pellets (either limestone or dolomite) are melted together in a blast furnace. The weld pool is shielded by this slag which moves along the full cross section of the joints as welding progresses. The process is initiated by an arc that heats up the slag. The arc is then extinguished by the conductive slag which is kept molten by its resistance to electric current passing between the electrode and the workpieces. ESW is the primary method used for cast weld assemblies of heavy sections due to one of its key characteristics of a high deposition rate. ESW is often used in structural box columns and wide flanges.

Much like submerged arc welding (SAW), ESW is also used for welding in the vertical position. Both utilize bare electrode wires fed continuously into a molten slag pool contained between water-cooled dams. The arc is then extinguished by pre-deposited flux. The molten pool of weld metal and base metal that is maintained by the heat generated from the resistance from the flux to the passage of current from the electrode to the base metal creates a molten resistor that is heated approximately to 3,500°F. If heat escapes the molten flux and weld pools too rapidly, the cross section of the weld could result in barrel shape, or incomplete fusion at the weld corners. The deposition weight of the weld, minimal joint prep involved, and vertical position needed all contributing to limiting the process to large weld projects or repairs normally using carbon or low alloy steel. The deposition rate is the relationship of the weight of the weld metal deposited to the weight of the electrode (or wire) consumed in making a weld. Weight of metal divided by weight of electrode used leaves you with the deposition efficiency expressed in pounds per hour. The higher the deposition rate, the lesser the amount of metal is wasted by not becoming part of the deposited weld metal. In short, ESW prevents a large percentage of welding consumables from being lost to slag, patter, and fume, giving fabricators the leading determinants of the cost of the effectiveness of a consumable. This can be very sought after depending on the end result asked to be achieved.

Like all fabricating procedures, depending on the final result of the part needed, there are disadvantages and advantages to each chosen. Unlike SAW, or other similar arc welding processes, no angular distortion or residual stresses occur with ESW because the weld is symmetrical in respect to its axis. Due to its vertical position, it produces a high welding speed creating a healthy amount of stress distributed across the weld. As mentioned before, its important the molten resistor is heated to approximately 3,500°F, as any higher could result in the weld quality being poor, allowing toughness from the grains in the fusion/heat-affected zone. ESW is also restricted to a vertical position with welding, which can be great to link thick metals together, but not advantageous for less thick parts.

Many factors have to be considered when selecting a welding process for a particular purpose or functionality. The types of welding needed to be performed, the types of steel, and the size and quality are only a few of topmost considered factors to be evaluated prior to any fabricating process. Electro-slag welding is no longer considered to be THE one option to link thick steel plates. With modern technological advances in ESW, its role has expanded beyond flanges to the construction sites of major high-ride bridges and buildings. ESW has been proving time and time again how cost-effective it can be for the reliable creation of large welds involving bridges and buildings.